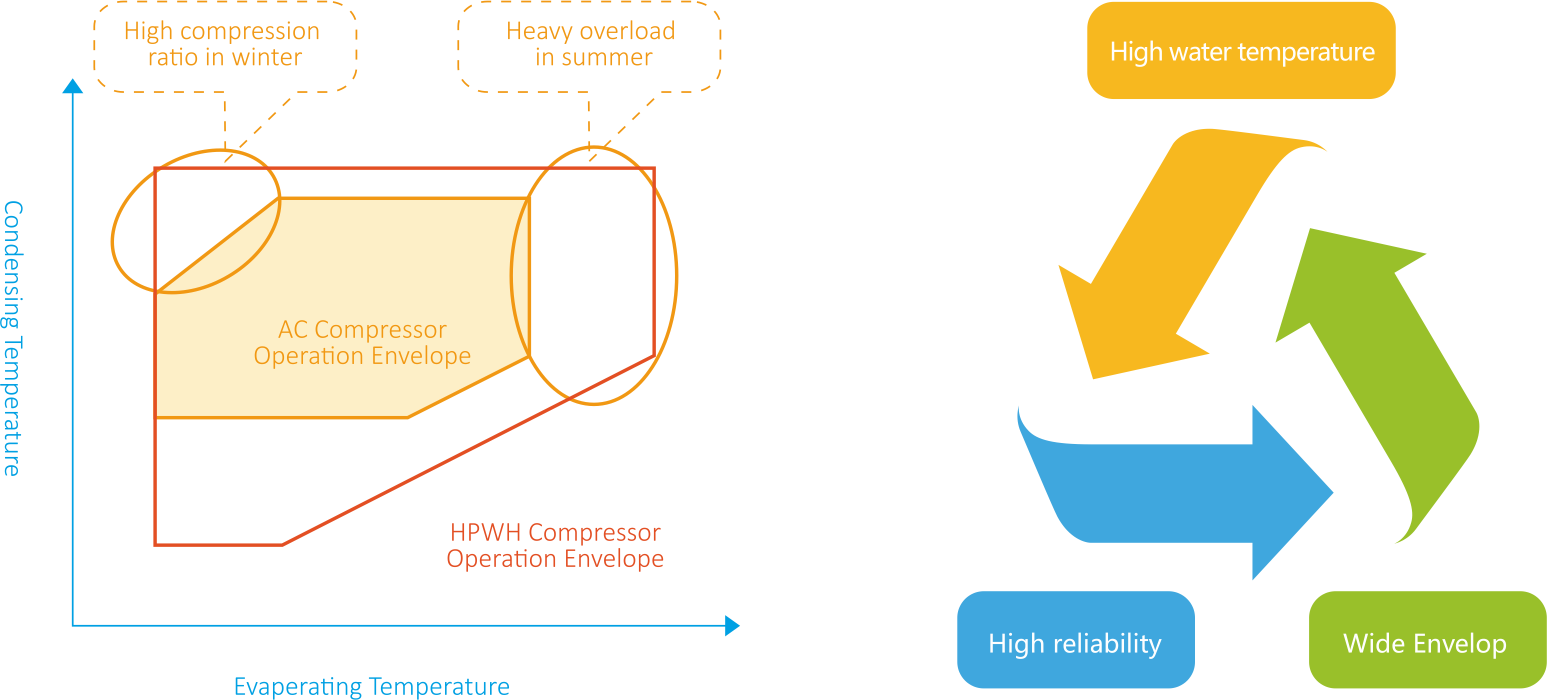

The Thermodynamic Solar System joins two incomplete technologies, the heat pump and the solar thermal collector. Heat pumps are quite efficient equipment but the heat they produce from their renewable component varies only according to changes in the temperature of the environment.

Thermal solar collectors are the best source of heat on hot and sunny days, but they are totally inefficient whenever there is no sun.

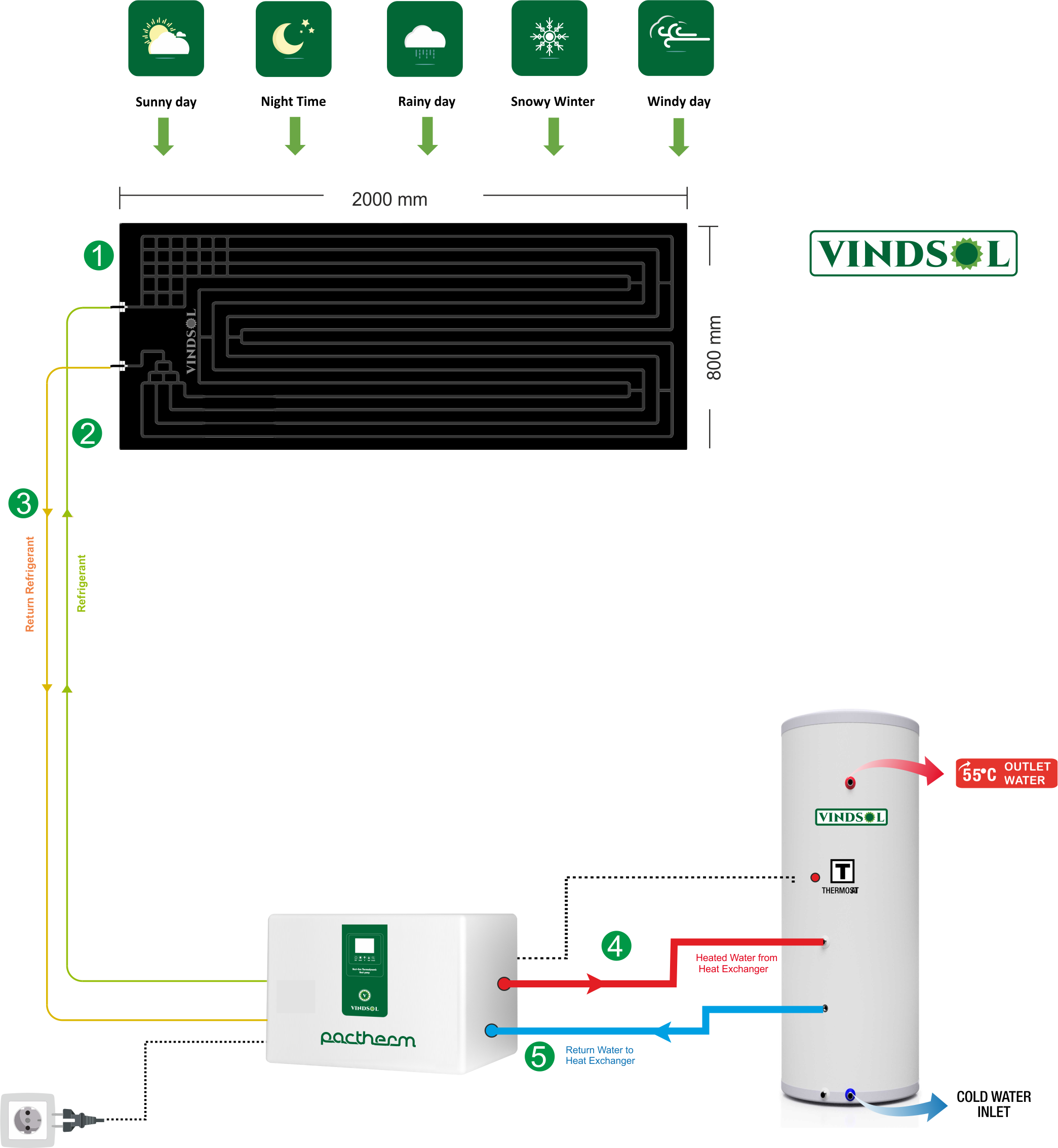

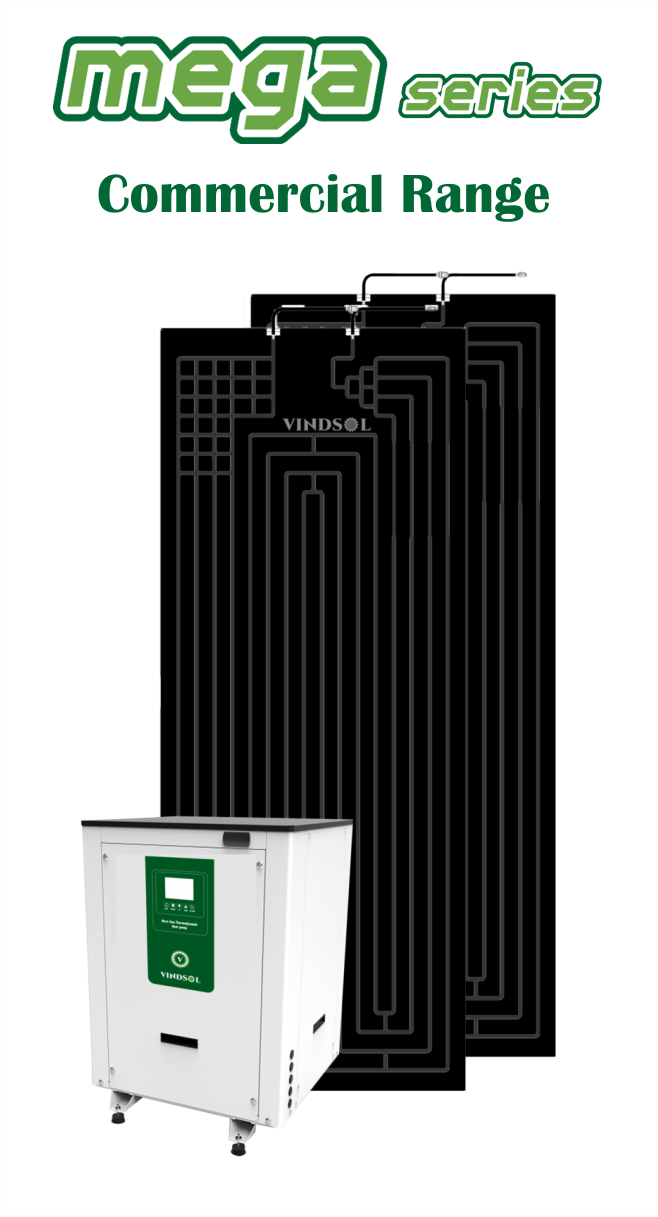

The thermodynamic Solar Technology manages to surpass the limitations of both the heat pump and solar collector. Through the cooling liquid (R134a or R407c ) which covers a closed circuit, the liquid goes into the solar panel and extract the thermal energy of sun , rain, wind, environment temperature and other climate factors . During this process the liquid gains heat in a more favorable way than a heat pump. after this stage , the heat it transferred to an exchanger with the help of a small compressor, which heats the water , The liquid cools down and the circuit is repeated.

As the fluid has a boiling temperature of approximately -30C, the thermodynamic heat pump in Bangalore works even when there is no sun and it even works at night, hail, rain, wind or shine, unlike the traditional solar thermal system.

The energy consumption of the system is basically the same as fridge compressor that makes the liquid circulate. there are no ventilators that help the evaporation process, of defrost cycles, which imply unnecessary energy consumption, unlike what happened with heat pump