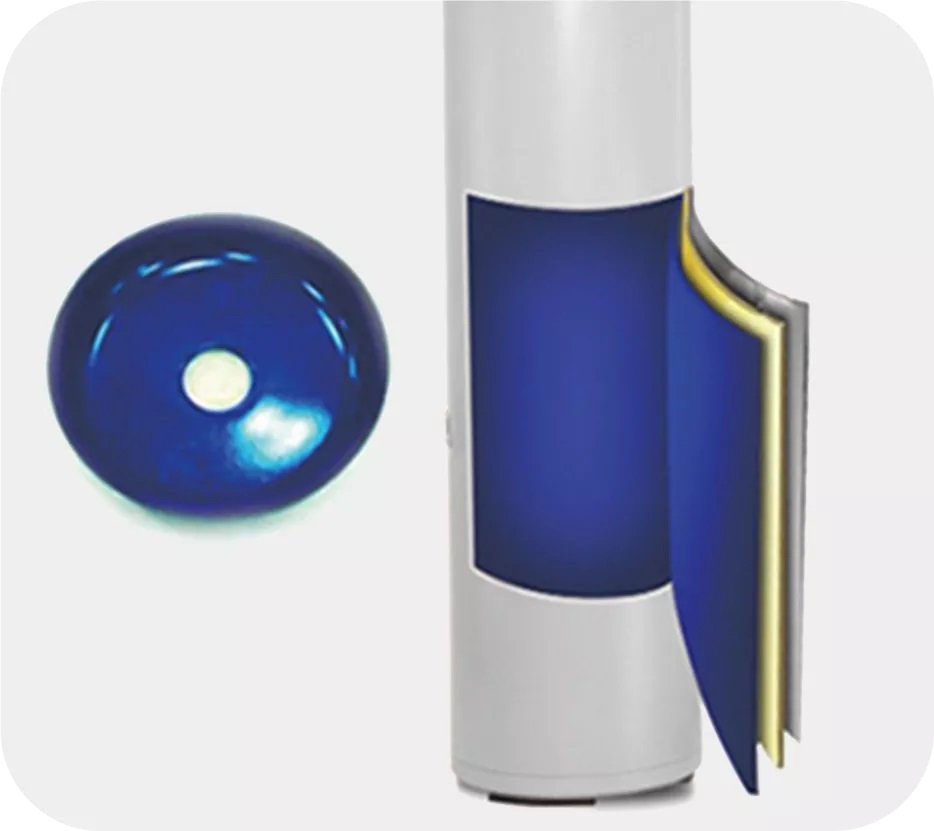

Introducing Vindsol Quartz Blue Glasslined Hot Water Storage Tanks with lowest standing loss and steel tank which is efficient and long lasting.

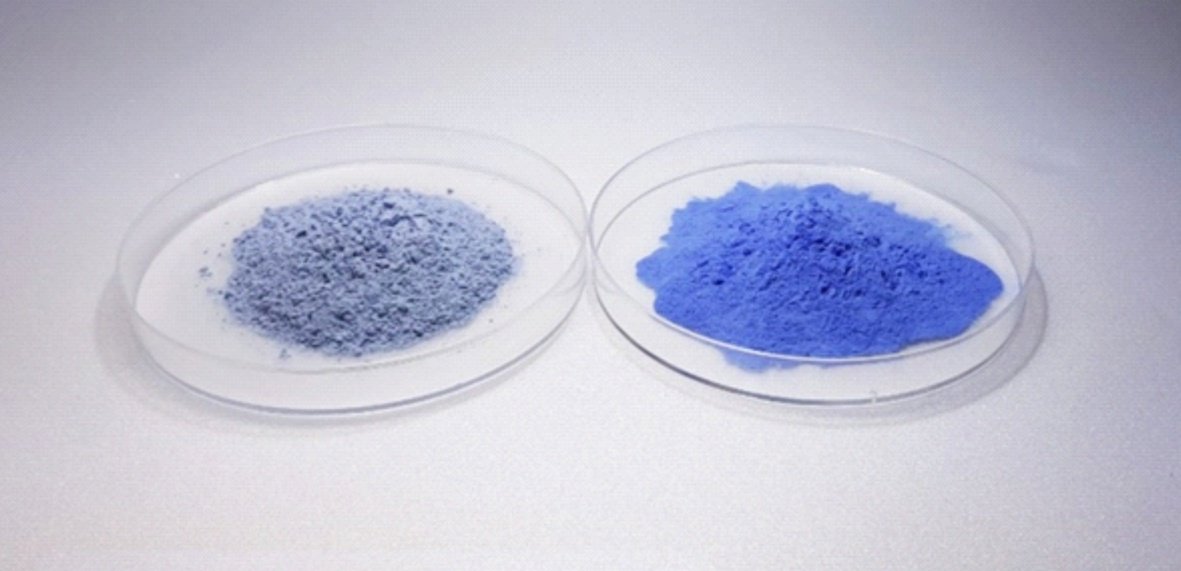

Our constant endeavour to make our products more durable, corrosion resistant and long lasting by using right mix of technology and raw material. The Glass Enamel Powder imported from Germany.

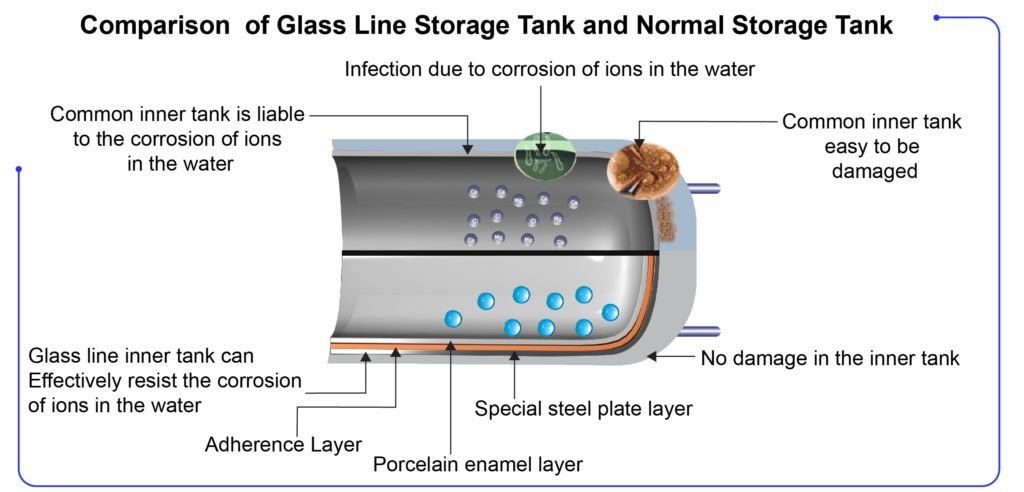

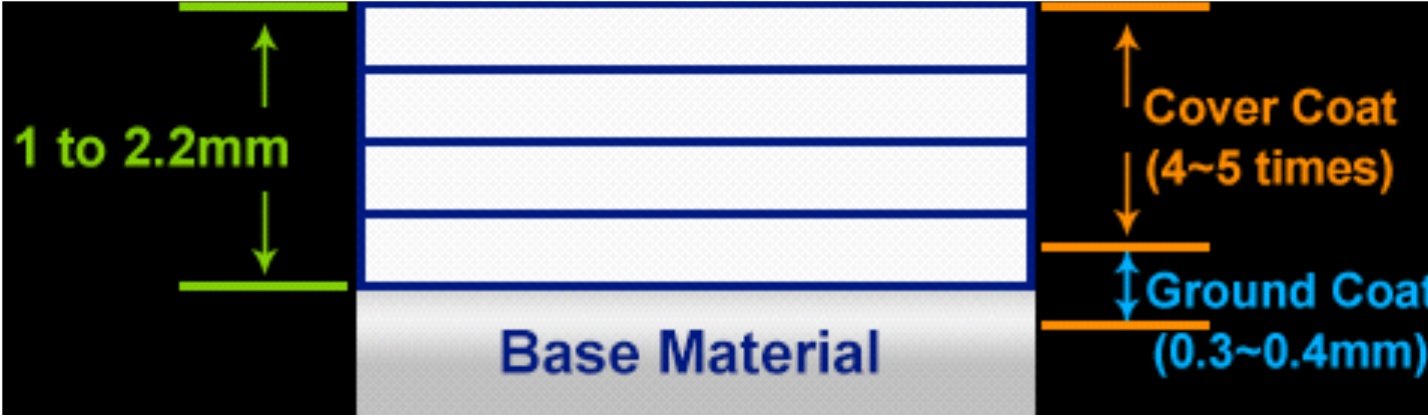

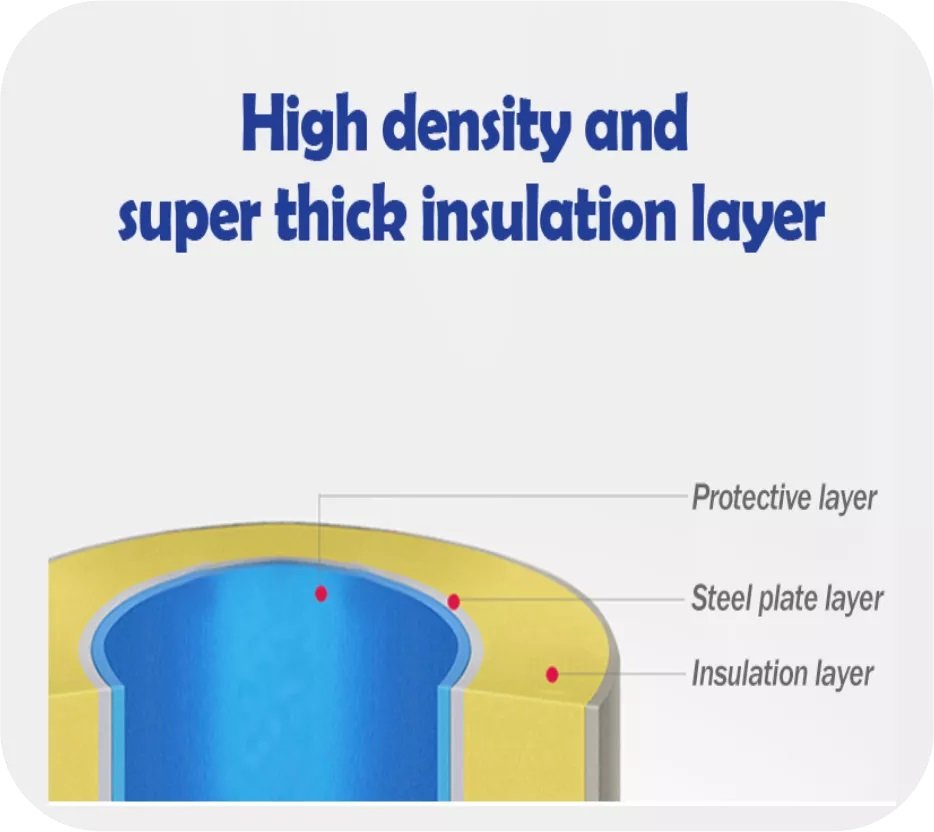

The Vindsol Quartz Blue Glass Lined storage tanks are an efficient option for solar water heaters. The inner tank is made from mild steel with a thin vitreous Porcelain enamelled glass coating inside of the vessel. The inner tank is encased with high density polyurethane insulation and a tough “Precoated Galvanised sheet” outer casing, fit to withstand India’s unforgiving climate!

This type of hot water storage tank is better suited for areas with hard water or poor water qualities, for example bore water or hard water with higher salt content. It also meets drinking water standards, and it can withstand temperatures up to 95 C.